Oxygen generators

The O-GEN series oxygen generators extract the available oxygen in the ambient air from the other gases by applying the Pressure Swing Adsorption (PSA) technology. During the PSA process compressed, cleaned ambient air is led to a molecular sieve bed, which allows the oxygen to pass through as a product gas, but adsorbs other gases. The sieve releases the adsorbed gases to the atmosphere when the outlet valve is closed and the bed pressure returns to ambient pressure. Subsequently, the bed will be purged with oxygen before fresh compressed air will enter for a new production cycle. In order to guarantee a constant product flow, O-GEN oxygen generators use modules of two molecular sieve beds, which alternatively switch between the adsorption and the regeneration phase. Under normal operating conditions and with correct maintenance the molecular sieve beds will have an almost indefinite lifetime.

Characteristics

| operating pressure | 5-6 barg |

| operating temp. range | 5 to 50 °C |

| ambient air temp. range | up to 45 °C |

| dew points (atmospheric) | < -60 °C |

| capacity | 1,02 to 94,9 Nm3/h |

| purity | up to 95 % |

STANDARD EQUIPMENT

• Set of External Feed Air Filters

• Adsorber Vessel in Carbon Steel

• Long life Pneumatic Valves

• Internal Piping & Fittings in SS316

• Exhaust Mufflers

• Air and Oxygen flow Regulation

• Control System with SIEMENS PLC

• WebControl

• Pressure Transmitter for Automated Idle-Mode

OPTIONAL EQUIPMENT

• Oxygen Analyzer with Zirconium-Oxide Sensor

• Electronic Product Flow Meter

• Feed Air / Product Moisture Analyser

• Oxygen Booster with Cylinder Filling System

• Feed Air / Product Temperature Transmitters

• Touch screen or Semi-Graphical Operator Interface

• Sterile Filters

Applications

• Aquaculture

• Feed Gas for Ozone Generators

• Glass blowing

• Leaching

• NOx Reduction for Fuel Burners

• Oxygen Lancing

• Welding, Brazing

• Wellness

• Feed Gas for Ozone Generators

• Glass blowing

• Leaching

• NOx Reduction for Fuel Burners

• Oxygen Lancing

• Welding, Brazing

• Wellness

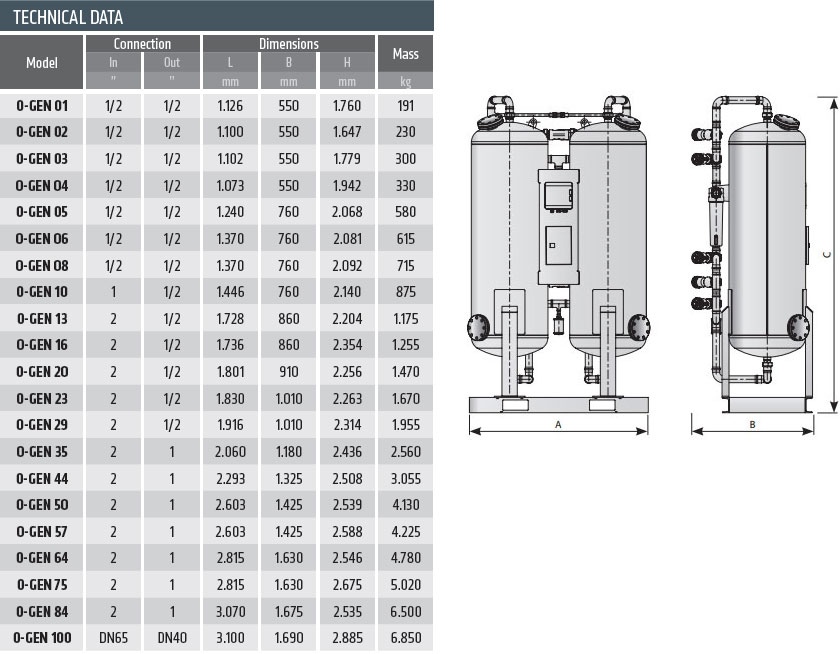

Technical data

25 Years Of Experience

With Quality At It’s Best!

Quick Links

Get In Touch

- Email: pure@purefiltration.net

- Phone: (+202) 38244517

- Mobile : 01007570066

© All Rights Reserved To Pure Filtration