R-DRY series

R-DRY heat regeneration adsorption dryers are designed for continuous separation of water vapour from compressed air thus lowering the dew point. R-Dry dryers have two columns that operate alternately. Adsorption takes place under pressure in the first column while the second column regenerates. A proven and robust design enables efficient and reliable operation, fast installation and simple maintenance.

R-DRY BVA – HEAT REGENERATION ADSORPTION DRYERS – COOLING WITH AMBIENT AIR

BVA type of dryer is suitable for applications running at mild ambient conditions. Due to regeneration in vacuum mode BVA type of dryers don’t consume any compressed air for the operation.

Average compressed air consumption: 0 %

R-DRY BP – HEAT REGENERATION ADSORPTION DRYERS – COOLING WITH PURGE AIR

R-DRY BP type of dryer is suitable for applications where low PDP is required at hotter and more humid ambient conditions and where compressed air can be utilised for cooling. A dryer consists of two columns, filled with desiccant beads, a blower, heater, controller with an LCD display, valves, manometers, and a support construction. A proven and robust design enables efficient and reliable operation, fast installation and simple maintenance.

Average compressed air consumption: 2 – 3 %

R-DRY BVL – HEAT REGENERATION ADSORPTION DRYERS – COOLING WITH CLOSED LOOP

Due to cooling in a closed loop BVL type of dryer is suitable for applications where low PDP is required at hotter and more humid ambient conditions. Due to cooling with water cooled air in a closed loop BVL type of dryers don’t consume any compressed air for the operation.

Average compressed air consumption: 0 %

R-DRY HOC F/P – HEAT REGENERATION ADSORPTION DRYERS – HEATED WITH FULL/PARTIAL STREAM

Characteristics

| operating presure | 4 to 11 bar |

| operating temp. range | 1,5 to 42,5 °C |

| pressure dew points | -40 °C |

| flow rate | 390 to 20.200 Nm3/h |

| average compressed air consumption | 0 – 3 % |

Applications

• compressed air systems

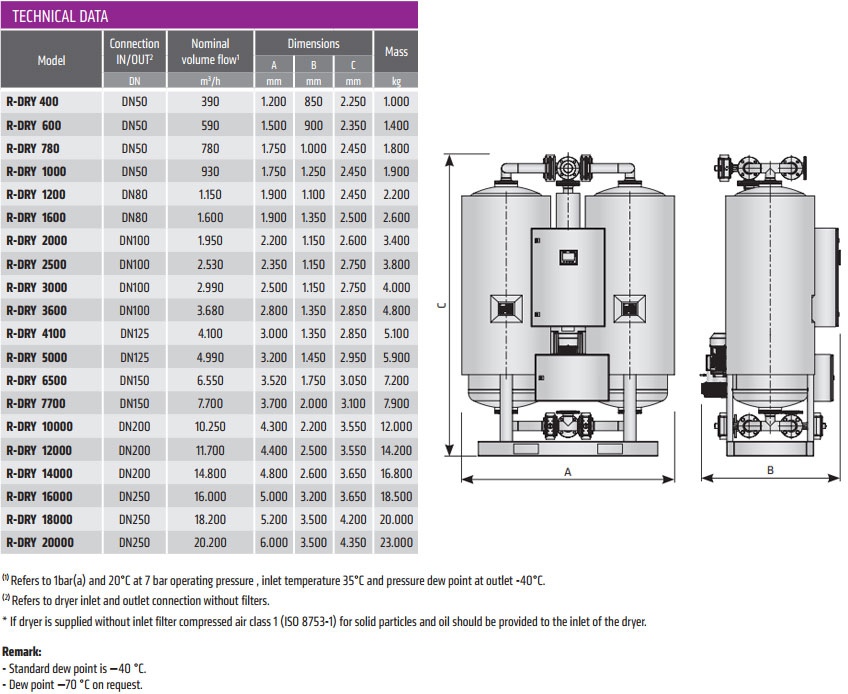

Technical data

25 Years Of Experience

With Quality At It’s Best!

Quick Links

Get In Touch

- Email: pure@purefiltration.net

- Phone: (+202) 38244517

- Mobile : 01007570066

© All Rights Reserved To Pure Filtration